Drum rotary dryer sawdust application:

1) Ore: ore,slag,mineral power,limestone, quartz, fluorite powder,iron ore,metal ore concentrates, metal tailings,etc.

2) Metal: metal powder, iron powder, iron filings, steel scrap, copper filings, etc.

3) Chemical industry: gypsum powder of desulphurization gypsum stir-frying half water model and building gypsum powder,clay,diatomaceous earth, kaolin,bauxite

4) Coal: raw coal,coal slime, coal,coal ash,coal cinder

5) Sand: sand,quartz sand,moulding sand,river sand

6) Various crystals: light calcium carbonate, activated clay, magnetic powder, graphite, mineral mud, clay, lime slurry, ore slurry, phosphorus slag, aluminum red mud, feldspar powder, fly ash, blue carbon, potassium, sodium, calcium, barium and alkali metal or silicate minerals in the

alkali metal.

7) Wood: sawdust, small wood chips, wood veneer.

8) Fertilizer: compound fertilizer, organic fertilizers, inorganic fertilizers, ammonium sulfate fertilizer

9) Agriculture: straw, grass, turf.

10) Animal manure: chicken manure, duck manure, cow dung, etc.

Drum rotary dryer sawdust structure:

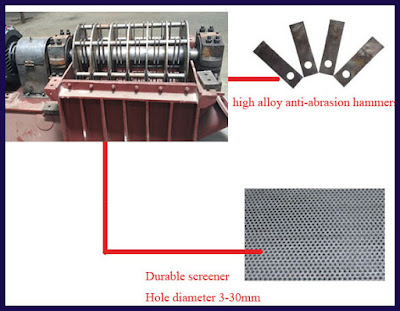

♦ drum rotary dryer sawdust is mainly composed of rotary part, lifting board, transmission part, supporting part and seal ring.

♦ drum rotary dryer sawdust produced by our company uses reasonable running parameters, and the coal and electricity consumption is reduced by over 10-15% and the output per machine is improved by over 10-15%, so that it has been widely used in the cement plants and ore benefication plants.

♦ Gear Material: Cast steel

♦ Discharging way: Downstream

♦ Drum Material: Heat-resisting steel sheet

Working Principle of wood chips rotary drum dryer

The raw material plate which is arranged reasonably with changeable angles in order, throws moisture materials into the rotary cylinder. Then water will be separated from the materials by hot air-flow and changed into vapour to be discharged into the atmosphere. Then the materials would be dried. Rotary dryer is used to dry slag, clay, limestone, It is mainly used for cement, chemical, metallurgical, building materials industries. Its advantages are as follows: high dry capacity, smooth rotation, low energy consumption, easy operation, high output and so on.

Whatsapp:+8615953143693

Email:emilyzhang@sdshuanghe.com

Skype:double.crane